Monocrystalline silicon wafers cells ingots find rfq detail silicon cell solar batteries charge storage devices from united states.

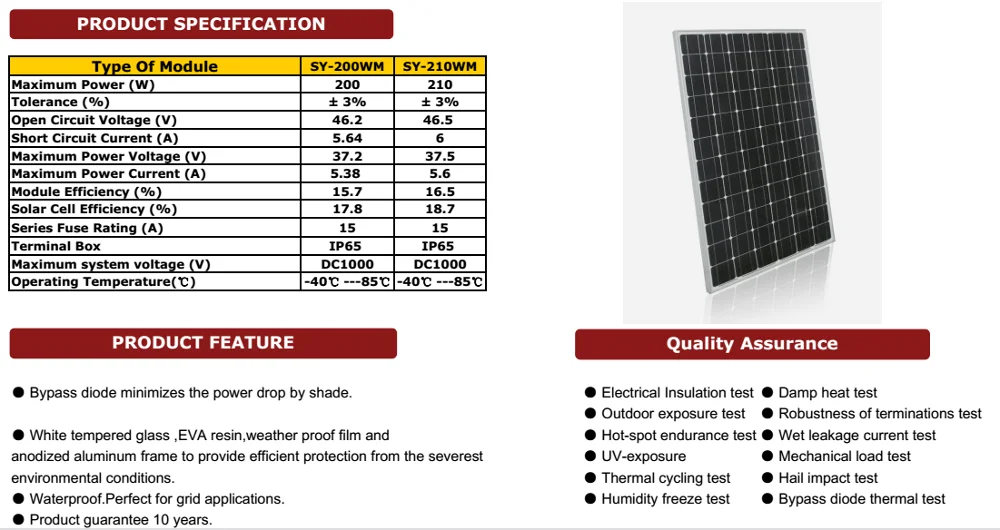

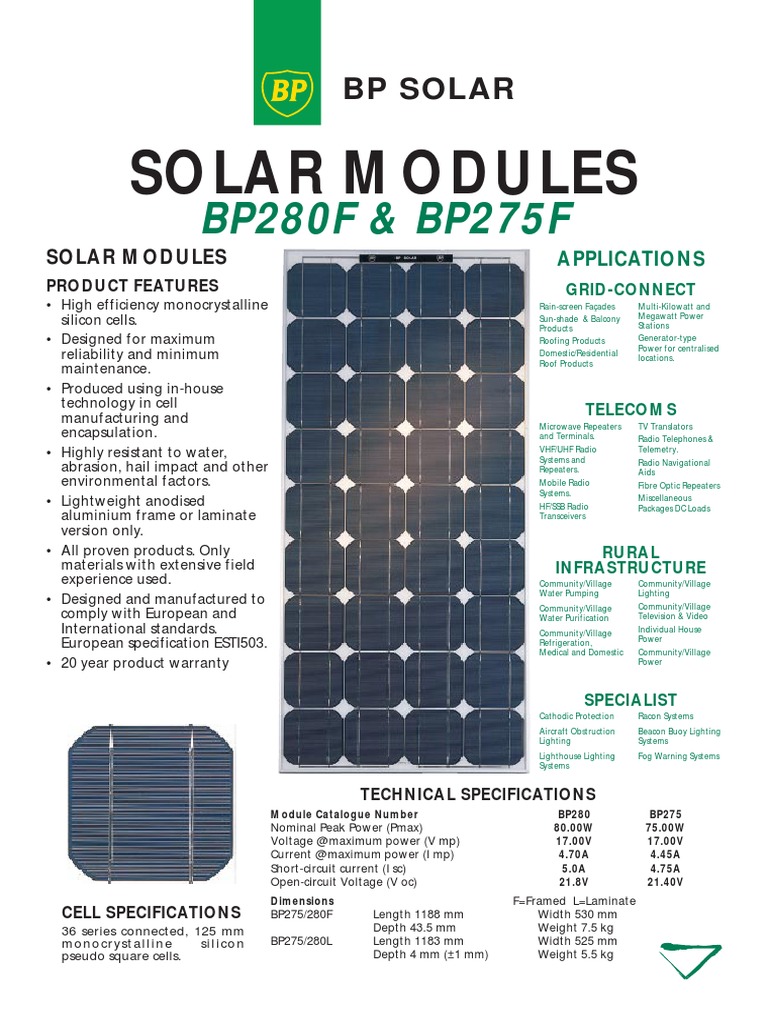

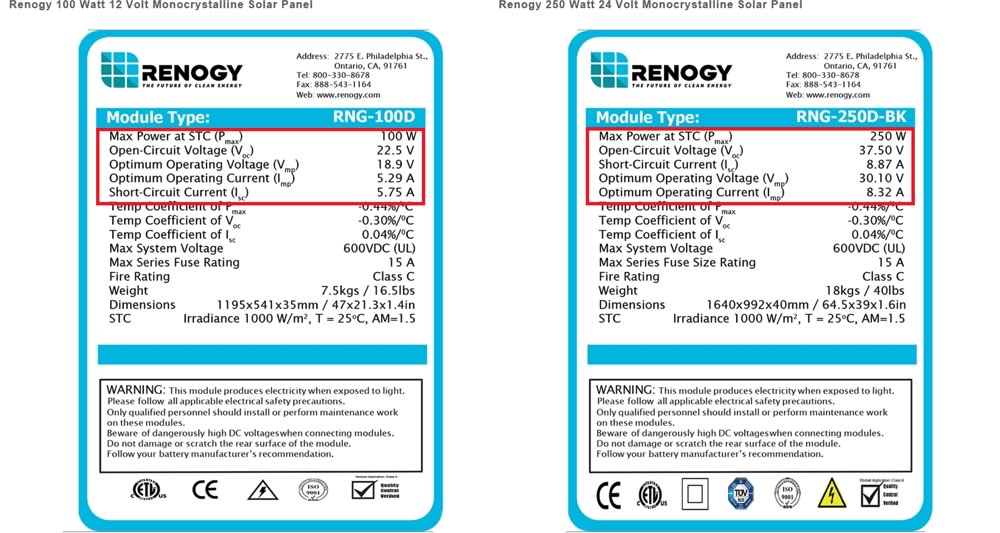

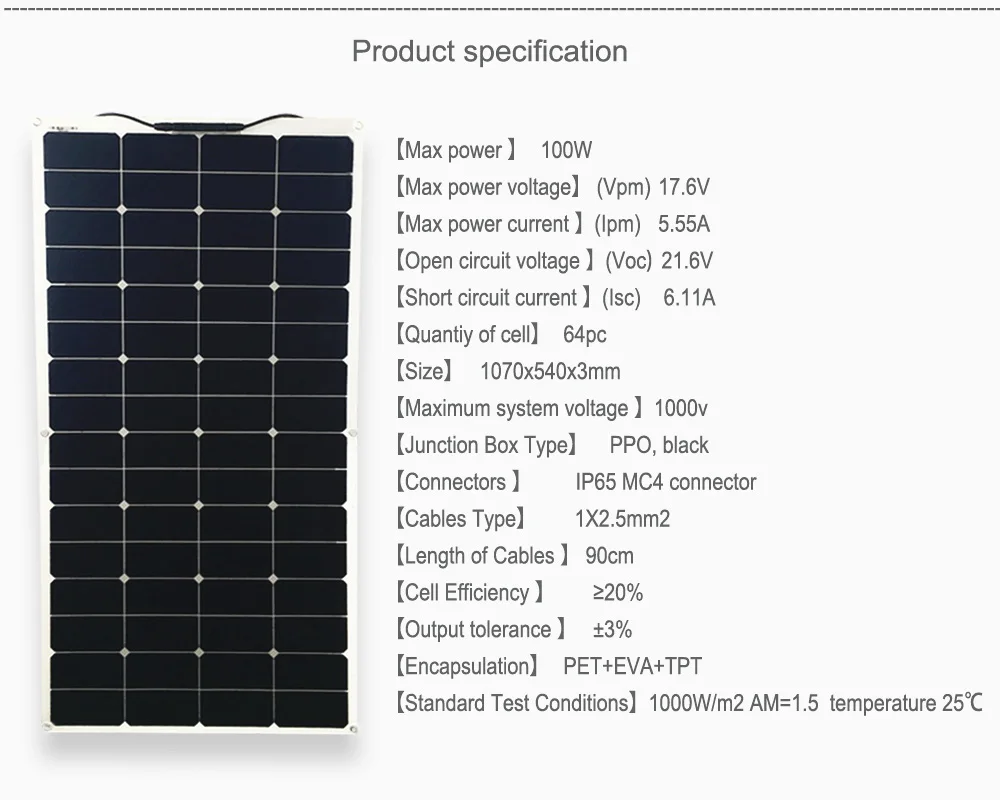

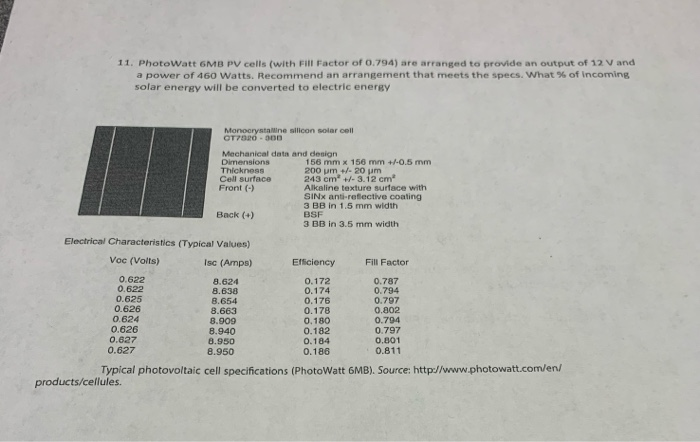

Monocrystalline silicon solar cells specifications.

Great attention has been paid to the manufacture and application of monocrystalline silicon cells which besides being used in space application have successfully been applied to navigation railway astronomy meteorology agriculture and animal husbandry and are now being expanded.

Silicon for monocrystalline solar cells is cut from an ingot of silicon that is a single unbroken crystal.

Monocrystalline solar panels are generally thought of as a premium solar product.

Monocrystalline panel efficiencies can range from 17 to 22.

To make solar cells for monocrystalline solar panels silicon is formed into bars and cut into wafers.

Crystalline silicon is the most common material for commercial applications.

Wang buxuan zhang zhenming in energy resources and environment 1982.

The main advantages of moncrystalline panels are higher efficiencies and sleeker aesthetics.

This makes them more efficient though more expensive than the newer and.

Monocrystalline solar panels usually have the highest efficiency and power capacity out of all types of solar panels.

This requires a very high purity silicon and is more difficult to manufacture than polycrystalline.

Mono crystalline cells polycrystalline cells and amorphous cells.

It has a well known standard process because silicon is abundant.

In monocrystalline solar panels each module is made from a single silicon crystal.

Monocrystalline silicon solar cells are designed to direct the free electrons in a path to power various appliances.

There are three basic types of photovoltaic cells.

Most residential installations use 60 cell monocrystalline silicon panels.